TOOLING Equipment

FULLY EQUIPPED TOOLROOM

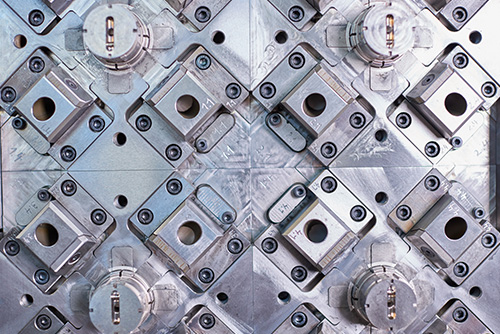

The manufacturing of plastic injection moulds is a core capability of Amper-Plastik. In contrast to other moulders we are not outsourcing the toolmaking but keep the knowhow in-house and invest regularly in our comprehensive machine outfit. In our toolroom we do not only manufacture the tools according to our internal specification but are also able to react quickly in case of possible tool breakages during production. As a side-effect our delivery performance is enhanced.

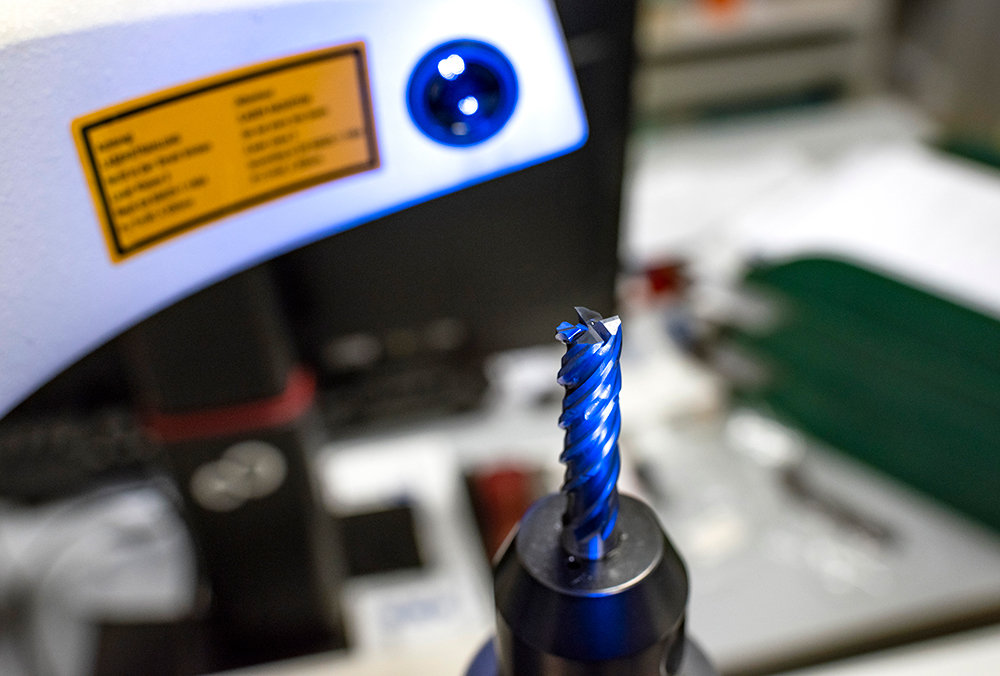

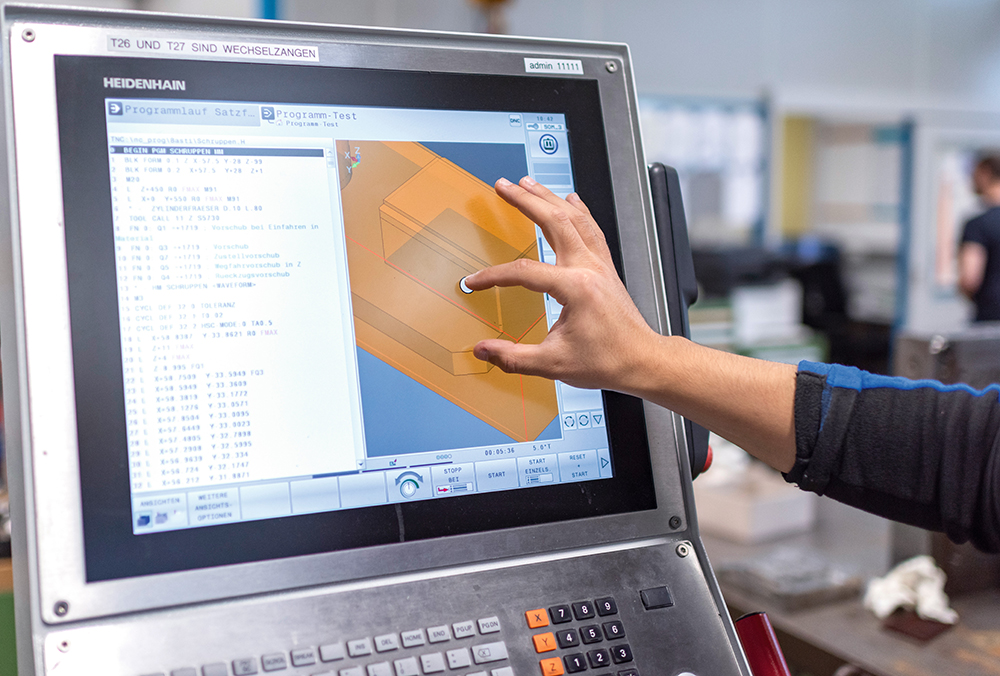

State-of-the-Art Technology

To strengthen our market position and future competitiveness and we frequently invest in upgrades of our technical equipment. Only recently the section EDM and wire-cutting was equipped with brand-new machinery.

Precision Machine Outfit

High-precision tools require a machine outfit of highest standards. Therefore we invest solely in machines manufactured by market leaders:

1. CNC-Cutting: Hermle, Germany and GF Machining Solutions, Switzerland

2. EDM and Wire-Cutting: Sodick Ltd., Japan

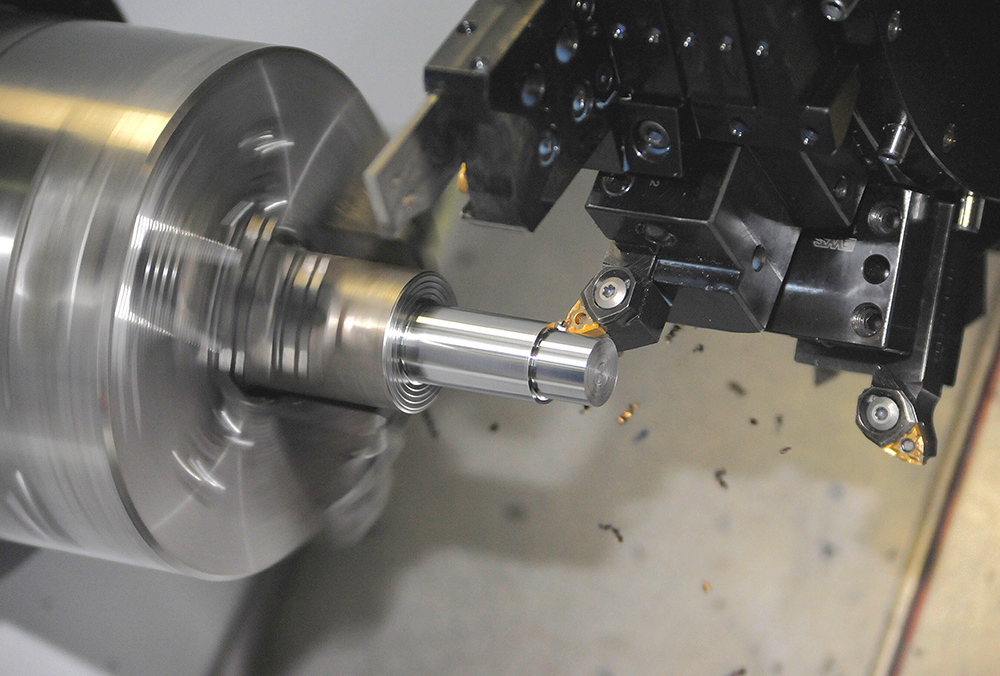

3. Turning: Weiler Werkzeugmaschinen GmbH, Germany

4. Grinding: KENT Industrial Co., Ltd., Taiwan

5. Laser Technology: ROFIN-SINAR Laser GmbH, USA/Germany

6. Ultrasonic Cleaning: FISA Group, France

Automation of Technical Processes

Trend-setting are our latest tool production lines. They are equipped with electrode and workpiece changers for an automatic processing, a requirement for highest degrees of capacity utilisation.

Cleaning and Maintenance of Injection Tools

Also for the maintenance processes we guarantee highest operational standards. Our injection tools are regularly cleaned by sequential ultrasonic bathes, increasing the tool life and assuring a high article quality in the long-run. For tool surfaces we utilize moveable dry ice jet blasting stations, removing plastic remains thoroughly and ecologically friendly, directly in process.

Tool Making and Maintenance

Different jobs require different specialists in order to perform the tasks in perfection. Therefore we have separated tool making and tool maintenance into two different sections, where they are realized by two independent and capable teams.