Development

OUR SERVICE, YOUR ADVANTAGE.

We develop and realize your plastic solutions. The development department is the technical core of Amper-Plastik. Our small but competent team with more than 100 years of experience in the fields of tooling and injection is always up-to-date, scanning the markets for innovations concerning raw materials, tooling or manufacturing technology. That is your advantage as our customer.

Extensive Development Support

Each plastic part is unique. We revise your articles’ design appropriate for tooling and injection. And in order to reduce cycle times to a minimum. For time is money and efficiency our standard.

Complementary Feasibility Studies

We do not develop at random. Detailed Feasibility Studies and FMEA-Analyses for your components are part of our daily business. To play it safe.

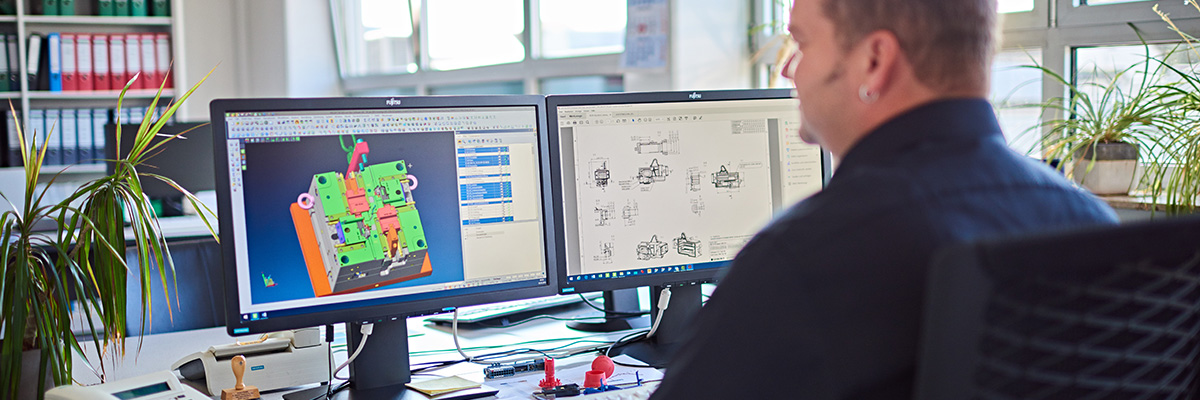

Moldflow Simulations

“Industry 4.0” is setting new standards. We implement them on a wide scale. Before moulding an article we simulate the process digitally by Moldflow Insight Premium®. Thereby we prevent mistakes, identify weak spots and avoid defects from an early stage. Furthermore we use it in the conceptual design of our moulds.

Selection of Thermoplastic Resins

Ten thousands of plastic resin grades are available in the market - Easy to lose track. Therefore we support you making the right choice for your application.

Secure Data Transfer

In today’s digital world data security is priority No. 1. We guarantee secure transfers for all exchanged data and offer multiple common software interfaces to prevent loss of information and time.

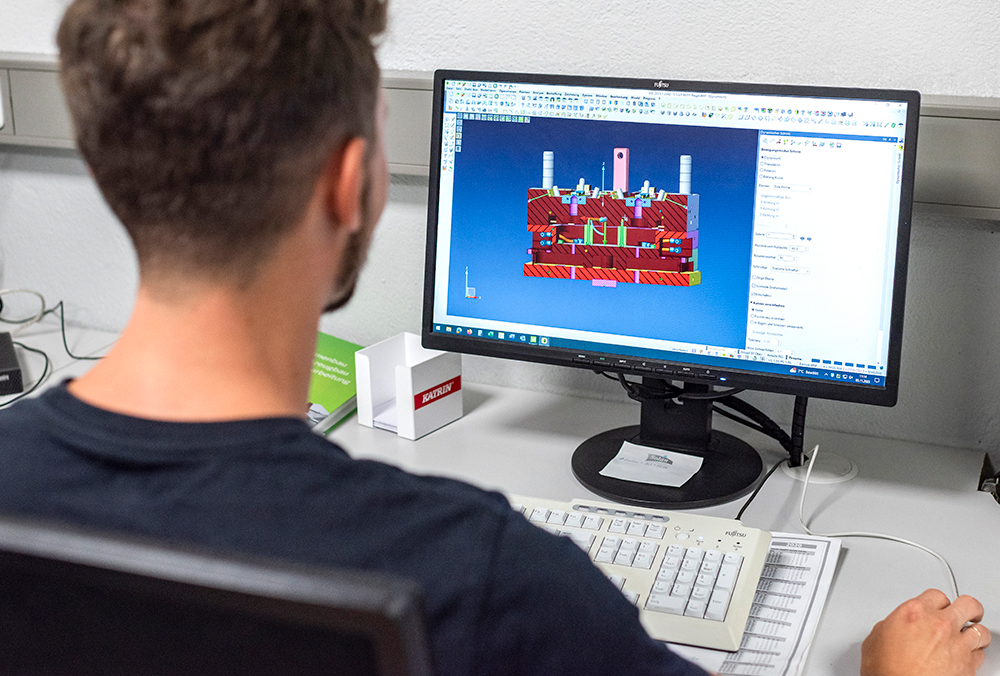

In-house Mould Design and Tool Management

- are our core capabilities. We design our injection tools in-house and manage them by comprehensive maintenance programmes. Our software-based approach implements preventive maintenance techniques and guarantees top-quality from Start-of-Production until End-of-Life.

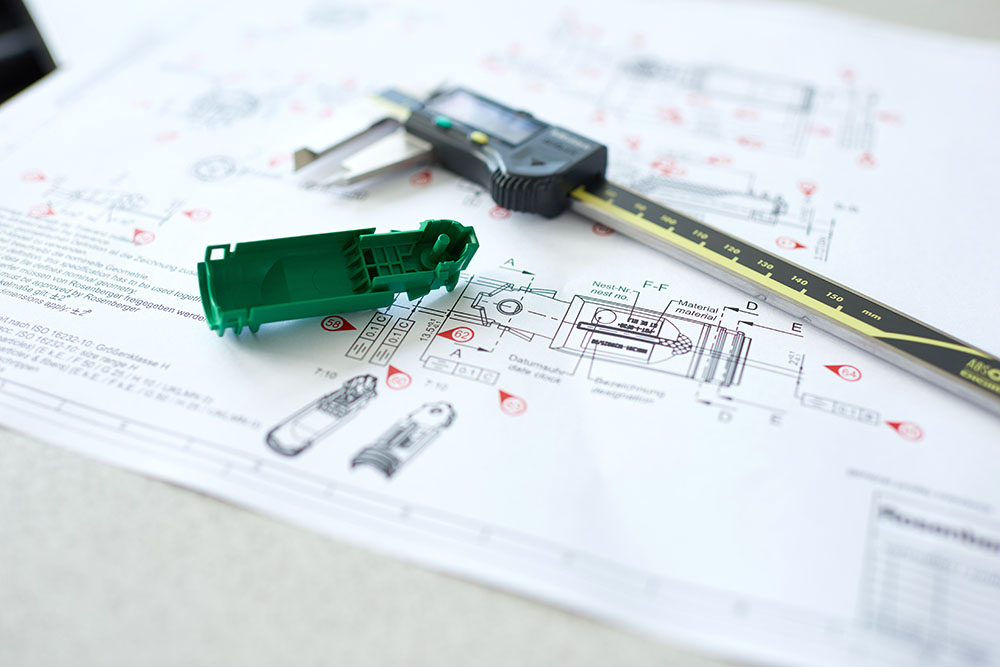

Modern Measurement Technology

Amper-Plastik is associated with precision moulding. Therefore we rely on state-of-the-art measuring equipment during the realisation of your project – from the quality of small series products to industrial mass-production – with CT-scans, tactile, optical, and laser measurements as well as series-accompanying tests.